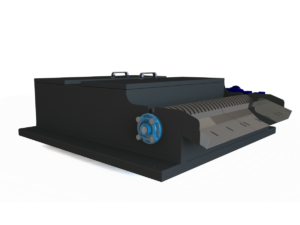

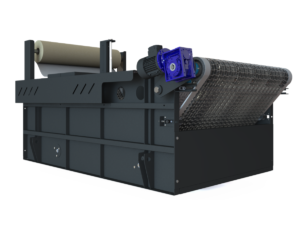

Description

The liquids used in many processes in the industry must be separated / filtered from the metal particles (ferromagnetic particles iron, steel, casting etc.) mixed with them during production.

Particularly during the processing of metal processing oils (Coolant and neat oils) used in the metal processing industry, a very high amount of ferro metal particles are mixed in their structures and separation of these particles in terms of the level of cleaning of the liquids is of great importance.

Magnetic separators and filtration units that we produce as Merta Filtration can be used alone in any application or they can be used as pre-filtration to paper filtration units. A complete filtration is provided here, as the paper filtration units also separate non-magnetic particles.